Common Types of Valves That Oil and Gas Engineers Should Know

Tony Mers • October 4, 2019

The demand for oil has experienced all-time high during the past decade. Statistics show that this consumption will rise to 109 million barrels by 2035, from 89 million barrels in 2012.

The demand for oil and gas products is rising. Thus, investing in this industry is a viable financial decision. You only need to ensure you get everything right from the start. For instance, do you know what a wellhead is? What are the different types of valves and tubing hangers that you can use in this industry? Take care and ensure you’re only using the right valve to meet your business goals. Don’t shy away from seeking advice from an engineer who is knowledgeable in this field. That’s how you’ll get value for your investment.

What does this mean? The oil and gas investors should employ clear measures to maximize on the rising demand. One way to do this is by investing more in the construction of wells for gas and oil products.

As an investor, you’ll need to engage a competent engineer to help you design and construct these wells. The engineer should be knowledgeable about any and all relevant laws and regulations. They should also advise you on the need to utilize a standardized wellhead design.

Do you know what a wellhead is? It’s the structure you place above your well to connect the tubing to the pipeline. It uses tubing hangers to contain pressure in your well, thus preventing collapse. The tubing hangers also play a vital role in sealing the well.

Why Does Your Wellhead need Valves and Tubing Hangers?

The oil and gas valves play a vital role in maintaining pressure and regulating the flow. As such, you need a competent engineer who knows more about tubing hangers and different types of valves. Let them explain to you the different types of valves and their functions, like how we've outlined below. Here is a list of the most common valves and the reason for their existence.

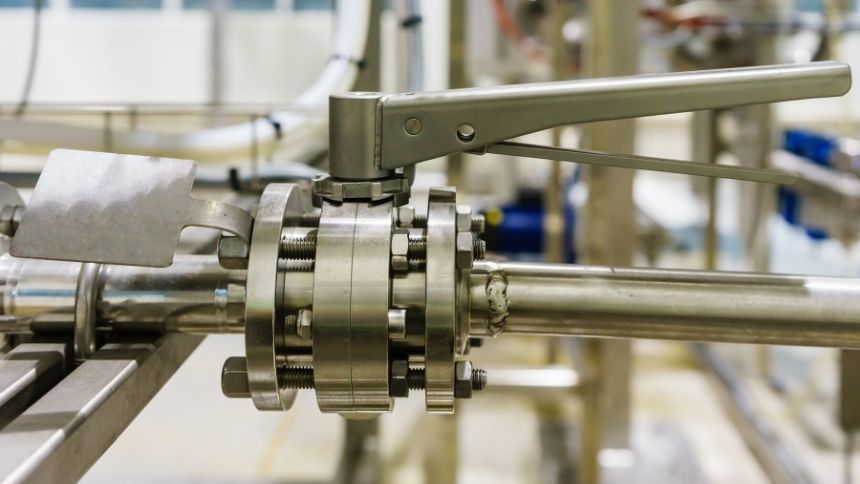

The Ball Valve:

Ball valves are common in oil, liquids and gas industries. The users love them due to their ease of turning on and off. Further, the valve has a tight sealing with very low torque. They operate using a quarter-turn rotational motion that uses a ball-shaped disc to control movement. Once you open the valve, the holes in the ball align with the body’s inlet thus allowing the oil and gas to pass. Manufacturers use several metals to manufacture these balls while they use softer materials for seats. This combination of materials allows the ball valves to operate at extremely low or high temperature.

Gate Valves:

The design of a gate valve allows it to either start or stop the flow of oil and gas. In most cases, you use this valve when you need a minimum flow restriction. In service, gate valves are either kept open or closed all the time. Opening this valve removes the gate disc allowing the content to pass through. It is bidirectional and boasts of high shut-off properties. However, they don’t open or close quickly. The gate valves are highly sensitive to vibration when you open them.

Butterfly Valves:

Butterfly valves, like ball valves, are designed to be a quarter-turn rotational valve. The oil and gas industries use this valve to start, stop and regulate the contents that flow through the pipeline. The valve is easy and fast to open, it also comes with a gearbox allowing you to connect the hand wheel by gear to its stem. The presence of a gearbox makes its operation easier but slow. You’re also required to install the butterfly valves at a minimum of 6 pipe diameters from the line elements. Other than being lightweight, and easier to use, they’re also available in small or large sizes. With this, the valve can cope with declining pressure and its high recovery.

The demand for oil and gas products is rising. Thus, investing in this industry is a viable financial decision. You only need to ensure you get everything right from the start. For instance, do you know what a wellhead is? What are the different types of valves and tubing hangers that you can use in this industry? Take care and ensure you’re only using the right valve to meet your business goals. Don’t shy away from seeking advice from an engineer who is knowledgeable in this field. That’s how you’ll get value for your investment.

Right now, there are over 3,000 facilities on the Outer Continental Shelf involved in the collection and treatment of oil and gas. These oils and gases are collected from wells -- a process that's performed using certain types of high pressure valves. Of course, different types of American ball valves offer different results and it's crucial that the right projects are executed with the right types of valves. Quite often, the types of valves being used are ball valves, sometimes referred to as pig ball valves or pig vales (as they are used in conjunction with pipeline pigging systems). Before sourcing and investing in valves, it is important to understand the degree to which these valves may differ from one another. Let's delve into some of the defining characteristics of ball valve types. Ball Valve Body Styles Before getting into the exact types of ball valves that are available at the moment, it's important to remember that there are actually four separate types of body styles. These include the single body, split body, top entry, and welded styles. The styles of ball valves available differ from the types of ball valves available. This means that there are number of potential variations that you can see in ball valves. The great thing about this variety is that it means that there is more potential applicability in ball valves than there would be otherwise. Full Port Ball Valves: Turning to the different body types of ball valves, we can first look at the full port ball valve. A full port ball valve is defined by the fact that it has an oversized ball. The oversized ball has a purpose -- it is the same size as the pipeline. This means that there will be less potential friction less than there would be if the ball wasn't the same size as the pipeline, and the flow involved is unrestricted. The valve is larger as well. Standard Port Valves: As their name suggests, standard port valve are quite usual. This means they're less expensive than some alternatives. This type of valve has a smaller ball, and therefore the valve itself is smaller as well. The flow going through the pipe will in turn be smaller and will typically be about one pipe size smaller than the valve's pipe size. This makes it more restricted. The V Port Ball Valve: The V port ball valve is named after its V-shaped seat. What this means is that the orifice through which the product flows can be more easily opened and closed to change its direction. While many like this idea, the construction of this type of valve means that it can't be used just anywhere. It typically needs to be utilized in a more secure site. When the valve is opened, it is usually opened at the "small end" first, which helps stabilize the flow control. Trunnion Ball Valve: Then there is the trunnion ball valve, which doesn't exactly give much away through its name. This type of valve will actually anchor the valve at the top and the bottom through a particular mechanism. This would be applied on larger and more high pressure valves. While this type of valve isn't going to fit everyone's needs, it can definitely be used for particularly high pressure projects. Manually Operated Valves: Finally, these types of valves can be closed more quickly than their counterparts. Though this is an advantage in some cases, it also means that there can be a risk of a water hammer. These can include an actuator, which can be pneumatically or motor operated, which will in turn be used for on/off flow control. The valve will also have a positioner, which transforms the control signal into an actuator position. The flexibility of this type of valve is certainly an advantage to most projects. Now that you're more familiar with the styles and types of ball valves, you'll be in a better position to make decisions that will support your needs. For more information, please contact us today.