Why Tiger Pig Valves Are Growing In Popularity

Tony Mers • October 15, 2019

For the past few years, Tiger Pig Valves have become popular, especially in the petroleum industry. Why is it happening? Because oil and petroleum products suppliers are looking for the best mediums through which they can distribute their products. You will notice that they regularly upgrade their distribution lines and change accessories, including the valves.

With the world producing more than 4 billion metric tons of oil every year, you can expect suppliers to keep exploring the best distribution products. If you are wondering why this valve is suitable, here is the answer: it is fabricated with unique characteristics. Here is a detailed look at these valves.

Quality engineering practices

Hydraulic gate valves are judged depending on the craftsmanship behind them. You will notice that the difference between the best and worst brands is the way they address the challenges that users face. When you look at the Tiger Pig Valves being sold in the North American market, you will notice that the manufacturers did their homework. They knew the troubles that distributors were going through, and they went ahead to make valves that prevent those troubles. Therefore, you can expect to pump petroleum products in an efficient way when you use these products.

Ability to handle high pressure

The fact that the world continues to increase its oil production every year with the discovery of new oil fields means that there will be increased pressure to use effective equipment as suppliers seek to reach every consumer. Therefore, the only thing that you can expect is an increase in demand for pig valves

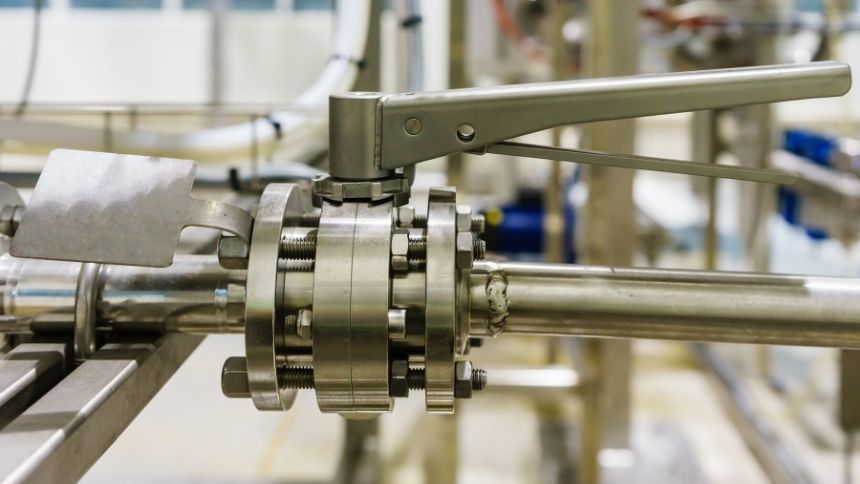

that can withstand more pressure. They are reliable in cases when the oil has to flow at a higher speed. With this high pressure ball valve, you can see that all these concerns have been addressed.

Made by qualified experts

We all know that experience is the best teacher. It teaches us skills that we would not find anywhere else. Through expertise, manufacturers can hack things that they would never otherwise understand. It is because there are unique skills that they learn through various challenges at work. Therefore, every successful task makes them better. That is the story of Tiger Pig Valves. You must have noticed that they have done away with all the things that made valves ineffective. In addition to that, their valve supply has better functionality than any other in the world.

Excellent customer service

Customer service is the other thing that makes Tiger brands stand out from the rest. You may choose to contact them about anything relating to pig valves and see their response. First, they know that every customer wants a fast response. They avoid delays in responses that might keep you waiting for too long when the matter could be urgent. In addition to that, they have made information about these valves available on various platforms. You can see it on their website, local publications, and social media. You can also learn more about their gate and ball valves by calling them directly on the phone.

Other high-quality products and accessories

You will also like Tiger Pig Valves because they come with many other accessories. Simply put, you do not have to look any further for more oil distribution products. The manufacturer knows that every consumer wants to match their products, and that is what they will give you. Therefore, if you notice that there is an extra accessory that you need, do not hesitate to inquire from them how it will get to you.

To sum it up, you can always get high-quality oil distribution products from Tiger. The fantastic performance and strength of their pig valves and tubing hangers is a demonstration that they can help to make oil distribution more efficient. They are also taking feedback from regular users of these products to find out how they can make them better. Next time you have a project, whether big or small, you should consider using these valves.

Right now, there are over 3,000 facilities on the Outer Continental Shelf involved in the collection and treatment of oil and gas. These oils and gases are collected from wells -- a process that's performed using certain types of high pressure valves. Of course, different types of American ball valves offer different results and it's crucial that the right projects are executed with the right types of valves. Quite often, the types of valves being used are ball valves, sometimes referred to as pig ball valves or pig vales (as they are used in conjunction with pipeline pigging systems). Before sourcing and investing in valves, it is important to understand the degree to which these valves may differ from one another. Let's delve into some of the defining characteristics of ball valve types. Ball Valve Body Styles Before getting into the exact types of ball valves that are available at the moment, it's important to remember that there are actually four separate types of body styles. These include the single body, split body, top entry, and welded styles. The styles of ball valves available differ from the types of ball valves available. This means that there are number of potential variations that you can see in ball valves. The great thing about this variety is that it means that there is more potential applicability in ball valves than there would be otherwise. Full Port Ball Valves: Turning to the different body types of ball valves, we can first look at the full port ball valve. A full port ball valve is defined by the fact that it has an oversized ball. The oversized ball has a purpose -- it is the same size as the pipeline. This means that there will be less potential friction less than there would be if the ball wasn't the same size as the pipeline, and the flow involved is unrestricted. The valve is larger as well. Standard Port Valves: As their name suggests, standard port valve are quite usual. This means they're less expensive than some alternatives. This type of valve has a smaller ball, and therefore the valve itself is smaller as well. The flow going through the pipe will in turn be smaller and will typically be about one pipe size smaller than the valve's pipe size. This makes it more restricted. The V Port Ball Valve: The V port ball valve is named after its V-shaped seat. What this means is that the orifice through which the product flows can be more easily opened and closed to change its direction. While many like this idea, the construction of this type of valve means that it can't be used just anywhere. It typically needs to be utilized in a more secure site. When the valve is opened, it is usually opened at the "small end" first, which helps stabilize the flow control. Trunnion Ball Valve: Then there is the trunnion ball valve, which doesn't exactly give much away through its name. This type of valve will actually anchor the valve at the top and the bottom through a particular mechanism. This would be applied on larger and more high pressure valves. While this type of valve isn't going to fit everyone's needs, it can definitely be used for particularly high pressure projects. Manually Operated Valves: Finally, these types of valves can be closed more quickly than their counterparts. Though this is an advantage in some cases, it also means that there can be a risk of a water hammer. These can include an actuator, which can be pneumatically or motor operated, which will in turn be used for on/off flow control. The valve will also have a positioner, which transforms the control signal into an actuator position. The flexibility of this type of valve is certainly an advantage to most projects. Now that you're more familiar with the styles and types of ball valves, you'll be in a better position to make decisions that will support your needs. For more information, please contact us today.