Applications of Trunnion Mounted Ball Valves

Paige Pesko • December 9, 2019

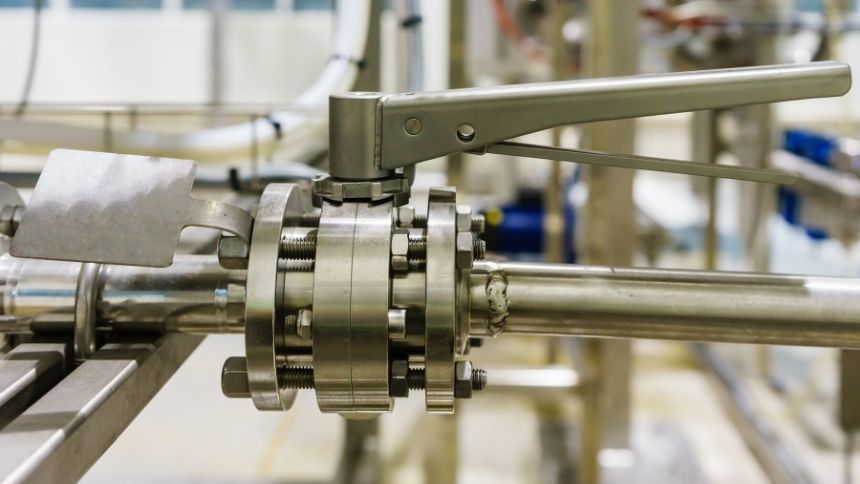

Widely admired for their extreme versatility, trunnion mounted ball valves have the ability to suit large-scale and high-pressure applications as well as compact and low-temperature circumstances. In addition, the customizable features, ease of operation, exceptional durability, and various other benefits of trunnion mounted ball valves allow many different industries to use them. To learn more about the many applications of trunnion mounted ball valves, continue reading.

Industries that utilize trunnion mounted ball valves

Oil and gas industries

Trunnion mounted ball valves are perfect for a wide range of applications among several oil and gas industries. Examples of oil and gas industries that utilize trunnion mounted ball valves include gas feed lines, field gas plants, industrial gas processing plants, oil refinery feedstock lines, and crude oil plants.

Pipeline industries

The ability of trunnion mounted ball valves to handle several different applications such as gasses, slurries, and liquids make them highly valuable in the pipeline industry.

Hydrocarbon industries

Because trunnion mounted ball valves are useful for the facilitation of hydrocarbon processing, they are extremely popular among hydrocarbon industries.

Power industries

Trunnion mounted ball valves are suitable for numerous applications such as turbines, skids, generators, compressors which are integral to the operation of power industries.

Chemical industries

Offering incredible safety, durability, and sealing capabilities, trunnion mounted ball valves suit a wide variety of chemical industries where such competencies are imperative.

Tiger Valve Company is a leading trunnion mounted ball valve

manufacturer and provider of engineered products for diversified industries. If you’re searching for robust valve solutions, check out our vast variety of high-quality valves which includes flanged floating ball valves, shut-off pig valves, and API-6A gate valves. We also have resilient seated butterfly valves, threaded swing check valves, trunnion mounted ball valves, and more. For more information regarding our high-quality products, contact us today.

Right now, there are over 3,000 facilities on the Outer Continental Shelf involved in the collection and treatment of oil and gas. These oils and gases are collected from wells -- a process that's performed using certain types of high pressure valves. Of course, different types of American ball valves offer different results and it's crucial that the right projects are executed with the right types of valves. Quite often, the types of valves being used are ball valves, sometimes referred to as pig ball valves or pig vales (as they are used in conjunction with pipeline pigging systems). Before sourcing and investing in valves, it is important to understand the degree to which these valves may differ from one another. Let's delve into some of the defining characteristics of ball valve types. Ball Valve Body Styles Before getting into the exact types of ball valves that are available at the moment, it's important to remember that there are actually four separate types of body styles. These include the single body, split body, top entry, and welded styles. The styles of ball valves available differ from the types of ball valves available. This means that there are number of potential variations that you can see in ball valves. The great thing about this variety is that it means that there is more potential applicability in ball valves than there would be otherwise. Full Port Ball Valves: Turning to the different body types of ball valves, we can first look at the full port ball valve. A full port ball valve is defined by the fact that it has an oversized ball. The oversized ball has a purpose -- it is the same size as the pipeline. This means that there will be less potential friction less than there would be if the ball wasn't the same size as the pipeline, and the flow involved is unrestricted. The valve is larger as well. Standard Port Valves: As their name suggests, standard port valve are quite usual. This means they're less expensive than some alternatives. This type of valve has a smaller ball, and therefore the valve itself is smaller as well. The flow going through the pipe will in turn be smaller and will typically be about one pipe size smaller than the valve's pipe size. This makes it more restricted. The V Port Ball Valve: The V port ball valve is named after its V-shaped seat. What this means is that the orifice through which the product flows can be more easily opened and closed to change its direction. While many like this idea, the construction of this type of valve means that it can't be used just anywhere. It typically needs to be utilized in a more secure site. When the valve is opened, it is usually opened at the "small end" first, which helps stabilize the flow control. Trunnion Ball Valve: Then there is the trunnion ball valve, which doesn't exactly give much away through its name. This type of valve will actually anchor the valve at the top and the bottom through a particular mechanism. This would be applied on larger and more high pressure valves. While this type of valve isn't going to fit everyone's needs, it can definitely be used for particularly high pressure projects. Manually Operated Valves: Finally, these types of valves can be closed more quickly than their counterparts. Though this is an advantage in some cases, it also means that there can be a risk of a water hammer. These can include an actuator, which can be pneumatically or motor operated, which will in turn be used for on/off flow control. The valve will also have a positioner, which transforms the control signal into an actuator position. The flexibility of this type of valve is certainly an advantage to most projects. Now that you're more familiar with the styles and types of ball valves, you'll be in a better position to make decisions that will support your needs. For more information, please contact us today.

Over 60% of our nation's energy is supplied by oil and gas. This makes it crucial for drillers to have the right equipment to ensure rigs and pipelines continue operating at optimal levels. If an improper valve is put in place, the operation could be slowed or even shut down completely, taking a toll on the overall supply delivered from that location. To help better understand the importance of valves, we’ll be taking a closer look at two important types: gate valves and ball valves. Gate Valves Gate valves are suitable for both underground and above ground applications and are designed to operate at either fully open or fully closed capacity. While they are typically installed on pipelines to serve as isolating valves, they should never be used for regulating or control. Gate valves are best used when the minimal amount of pressure loss needs to be applied, as there are no obstructions when it is fully opened and when a free bore is needed. This type of valve is multi-turn, meaning that the operation relies on a threaded stem. The main benefit of this slower operation is a reduction of hydraulic shock caused by fluid changing direction or stopping suddenly. Gate valves can be used in many conditions, including: The movement of wastewater or neutral liquids that are between the temperatures of -20 to +70 degrees Celsius, with a maximum flow velocity of 5 m/s, and a standard pressure differential of 16 bar units. The movement of gases between the temperatures of -20 to +60 degrees Celsius, with a maximum flow velocity of 20 m/s and a pressure difference of 16 bar units. Gate valves can be found in two different types: wedge and parallel. Wedge shapes utilize two inclined seats and an included gate, while parallel types use a flat gate. The main difference lies in the methods of sealing with parallel gates relying on line force to aid in sealing, and wedge gates relying on torque. Overall, gate valve s are some of the most common types to be used, able to offer an easy method of valve sealing that is capable of operating even at high temperatures. Ball Valves Ball valves serve as a good option for shut-off valves. With a quick 90-degree turn, you can easily open and close the valve, reducing both time and the risk of leaking. Ball valves can be found in both full bore and reduced bore varieties, with full bore fitting the diameter of the pipeline, and the reduced bore having a smaller diameter. Full bore ball valves are more highly sought after due in large part to their ability to minimize pressure loss. Ball valves should only be used fully open or fully closed. This type is not recommended for flow regulation, as uneven pressure can cause the valve seat to become malformed over time. If this occurs, the potential for leaks increases. The biggest advantage of using this type of valve is the lowered cost of manufacturing and maintenance. Additionally, they are compact, easy to open and close, and require no lubrication while still maintaining a high level of sealing. Overall, high pressure ball valves are great for applications that require tight and secure shut off capabilities. This can be especially important when working with gases, as any leaks could be potentially hazardous. Knowing Your Needs These valve types are some of the most commonly used throughout many industries. Understanding their differences and their applications will ensure proper operation. If you have any questions or want to know more about what types of valves are best for your operation, don’t hesitate to reach out. The sooner you start to better understand your systems, the sooner you can begin running more efficiently overall.