How to Choose the Right Pig Valve Supplier

Tony Mers • September 4, 2019

How to Choose the Right Pig Valve Supplier

Choosing the right pig valves for your operations can be a challenge. With a rise in popularity of pig valve suppliers, it's hard to know which valve supply dependable service and products, and which ones should be avoided. If you're looking for a supplier to provide you with the best pig valves, but you're not sure how to begin your search, then follow our simple guide below to get started today.

The Growth of the Valve Supply Industry

First and foremost, it's prudent to have an awareness about the current state of the pig valve

supply industry as a whole. Due to developments in manufacturing, commerce, and technology, there are more sources for pig valves than ever before. Take, for example, the recent numbers from the Valve World Americas Expo and Conference. Though it's a niche interest, the conference has seen remarkable growth in recent years. As part of the Valve World Americas Expo and Conference, over 320 companies exhibited with a total of 4,141 visitors for the entire event, including nearly 450 conference attendees in the year 2017. If these numbers are any reliable indicator, then you can expect the valve supply market to continue its growth in the years to come. Being prepared with a dependable supplier will help you stay ahead of the curve, and your competitors.

The Importance of Individual Consultation

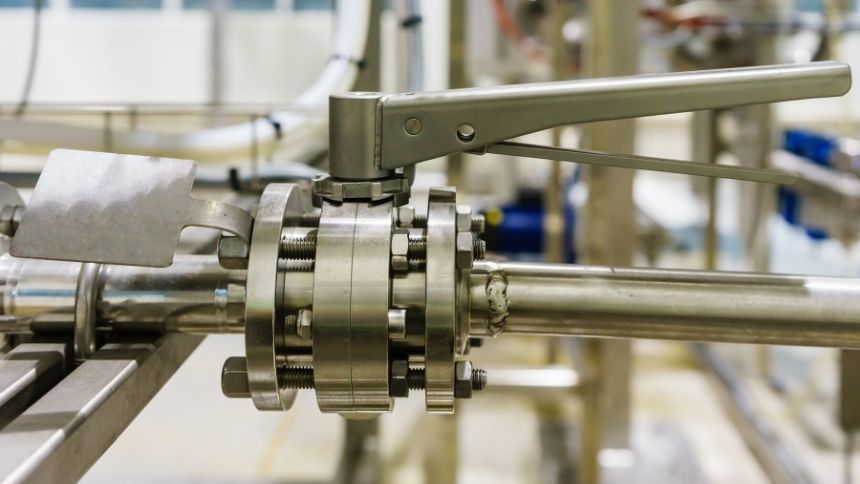

Whether you're looking for ball valves, tubing hangers, or gate valves, the value of consultation from knowledgeable industry experts cannot be overlooked. By tailoring options to fit your unique needs, you are much better positioned to find the valves you're looking for, while also establishing a solid, long lasting relationship with your supplier. If custom parts are required, it helps to know from the start that you can trust your supplier to offer the necessary services. Budget concerns, of course, are another concern for any company looking to acquire pig valves. A trusted supplier communicates its fees and costs with transparency. This makes it much easier to develop a sustainable financial plan for your acquisitions.

While it's no surprise that finding the right valve supplier can be a challenge, with sufficient education and communication, your company can improve the odds of finding a company that makes business transactions go as smooth as possible. As the industry will only continue to grow, it's wise to be proactive in establishing a positive relationship with a supplier sooner rather than later. If you're still not settled on a valve supply company, then contact us today. With industry expertise and years of demonstrated experience, we'd love to help you find a solution that meets your needs.

Right now, there are over 3,000 facilities on the Outer Continental Shelf involved in the collection and treatment of oil and gas. These oils and gases are collected from wells -- a process that's performed using certain types of high pressure valves. Of course, different types of American ball valves offer different results and it's crucial that the right projects are executed with the right types of valves. Quite often, the types of valves being used are ball valves, sometimes referred to as pig ball valves or pig vales (as they are used in conjunction with pipeline pigging systems). Before sourcing and investing in valves, it is important to understand the degree to which these valves may differ from one another. Let's delve into some of the defining characteristics of ball valve types. Ball Valve Body Styles Before getting into the exact types of ball valves that are available at the moment, it's important to remember that there are actually four separate types of body styles. These include the single body, split body, top entry, and welded styles. The styles of ball valves available differ from the types of ball valves available. This means that there are number of potential variations that you can see in ball valves. The great thing about this variety is that it means that there is more potential applicability in ball valves than there would be otherwise. Full Port Ball Valves: Turning to the different body types of ball valves, we can first look at the full port ball valve. A full port ball valve is defined by the fact that it has an oversized ball. The oversized ball has a purpose -- it is the same size as the pipeline. This means that there will be less potential friction less than there would be if the ball wasn't the same size as the pipeline, and the flow involved is unrestricted. The valve is larger as well. Standard Port Valves: As their name suggests, standard port valve are quite usual. This means they're less expensive than some alternatives. This type of valve has a smaller ball, and therefore the valve itself is smaller as well. The flow going through the pipe will in turn be smaller and will typically be about one pipe size smaller than the valve's pipe size. This makes it more restricted. The V Port Ball Valve: The V port ball valve is named after its V-shaped seat. What this means is that the orifice through which the product flows can be more easily opened and closed to change its direction. While many like this idea, the construction of this type of valve means that it can't be used just anywhere. It typically needs to be utilized in a more secure site. When the valve is opened, it is usually opened at the "small end" first, which helps stabilize the flow control. Trunnion Ball Valve: Then there is the trunnion ball valve, which doesn't exactly give much away through its name. This type of valve will actually anchor the valve at the top and the bottom through a particular mechanism. This would be applied on larger and more high pressure valves. While this type of valve isn't going to fit everyone's needs, it can definitely be used for particularly high pressure projects. Manually Operated Valves: Finally, these types of valves can be closed more quickly than their counterparts. Though this is an advantage in some cases, it also means that there can be a risk of a water hammer. These can include an actuator, which can be pneumatically or motor operated, which will in turn be used for on/off flow control. The valve will also have a positioner, which transforms the control signal into an actuator position. The flexibility of this type of valve is certainly an advantage to most projects. Now that you're more familiar with the styles and types of ball valves, you'll be in a better position to make decisions that will support your needs. For more information, please contact us today.