How Do High Pressure Hydraulic Valves Work?

Tony Mers • July 26, 2019

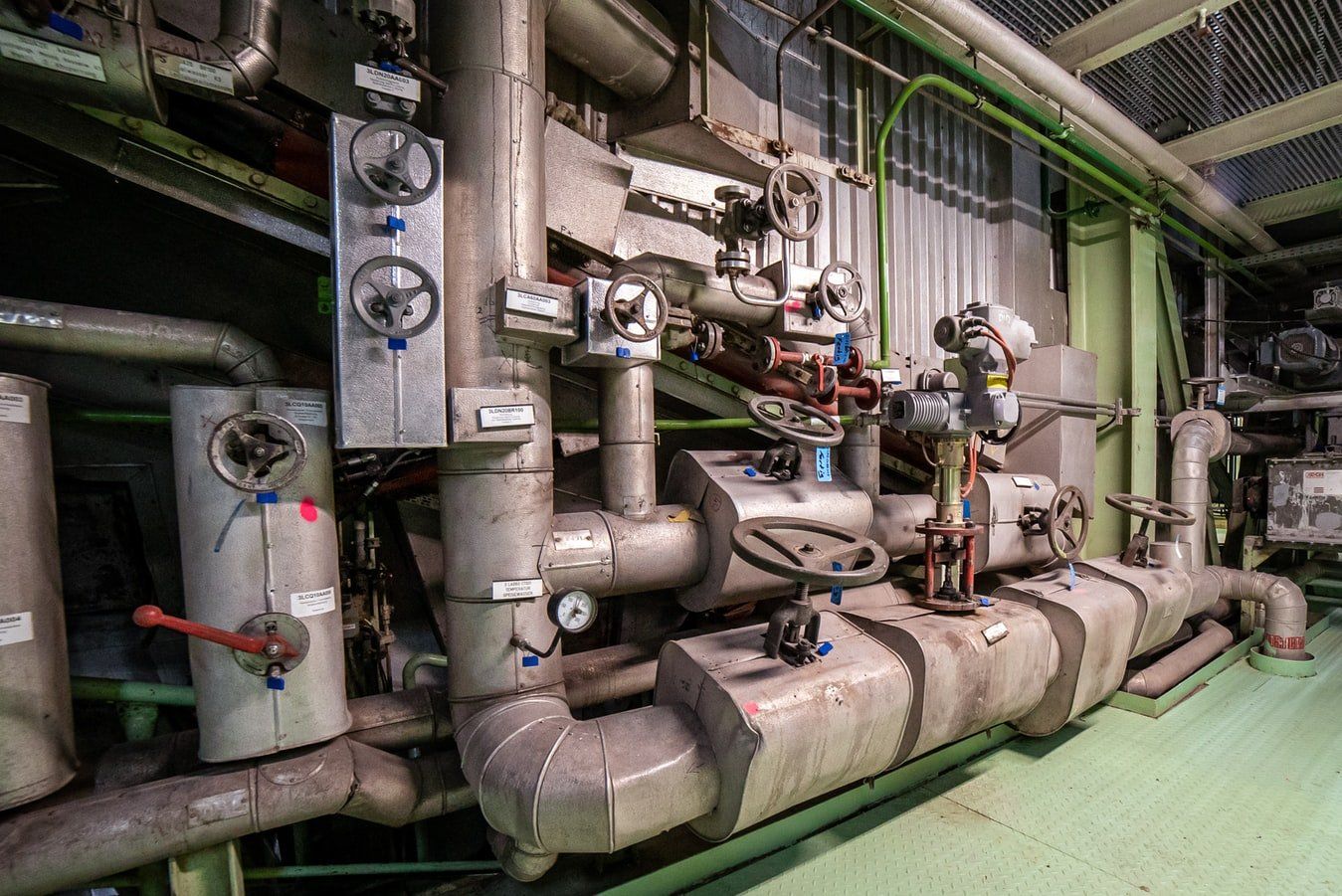

High pressure valves are used in a variety of industries, from global oil production (around 13% of which is produced by the U.S.) to aerospace manufacturing. In fact, they are found in virtually every hydraulic system and work to keep system pressures safely below a desired upper limit. Generally speaking, there are five different types of high pressure valves; let's take a look at each of them.

Relief:

Fluid power systems operate within a preset pressure range. This range is a function of the forces the system must generate to do the required work; if these forces are not controlled or limited, they can cause damage to the (sometimes extremely) expensive equipment and fluid power components. Relief valves act as the safeguards which limit maximum pressure by diverting excess oil when the pressures get too high.

Reducing:

Reducing valves are the most practical components when it comes to maintaining secondary, lower pressure in a hydraulic system. They're the only high pressure valve

on this list that remains open and close when subjected to sufficient downstream pressure. They come in two types: direct acting and pilot operated.

Sequence:

Some circuits have more than one actuator, so it's necessary to drive these actuators (such as cylinders) in a specific order or sequence. Limit switches, timers, and other electrical control devices are used for this purpose.

Counterbalance:

These high pressure valves are primarily used to set pressure in part of a circuit, usually to counterbalance a weight or external force. The valve's main port is connected to the cylinder's rod end, and the pressure setting is slightly higher than that required to keep the load from free-falling.

Unloading:

Unsurprisingly, unloading valves are used to unload pumps. They direct pump output flow (which is usually the output of one pump in a multi-pump system) directly to a reservoir at low pressure once system pressure has been reached. When an external pilot signal acting on the opposite end of the valve spool exerts a force large enough to exceed that exerted by the spring, the valve spool shifts and diverts pump outflow to the reservoir.

Finding the right valve for the job -- whether you need ball valves or gate valves -- is crucial in high pressure situations.

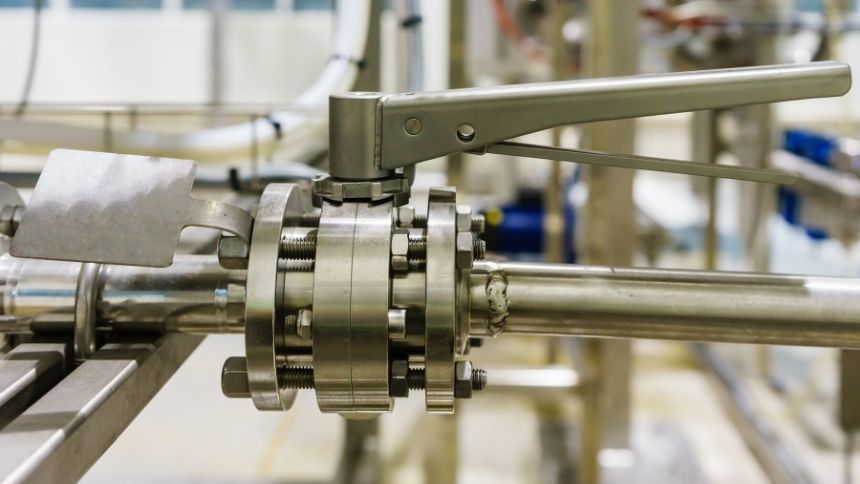

Right now, there are over 3,000 facilities on the Outer Continental Shelf involved in the collection and treatment of oil and gas. These oils and gases are collected from wells -- a process that's performed using certain types of high pressure valves. Of course, different types of American ball valves offer different results and it's crucial that the right projects are executed with the right types of valves. Quite often, the types of valves being used are ball valves, sometimes referred to as pig ball valves or pig vales (as they are used in conjunction with pipeline pigging systems). Before sourcing and investing in valves, it is important to understand the degree to which these valves may differ from one another. Let's delve into some of the defining characteristics of ball valve types. Ball Valve Body Styles Before getting into the exact types of ball valves that are available at the moment, it's important to remember that there are actually four separate types of body styles. These include the single body, split body, top entry, and welded styles. The styles of ball valves available differ from the types of ball valves available. This means that there are number of potential variations that you can see in ball valves. The great thing about this variety is that it means that there is more potential applicability in ball valves than there would be otherwise. Full Port Ball Valves: Turning to the different body types of ball valves, we can first look at the full port ball valve. A full port ball valve is defined by the fact that it has an oversized ball. The oversized ball has a purpose -- it is the same size as the pipeline. This means that there will be less potential friction less than there would be if the ball wasn't the same size as the pipeline, and the flow involved is unrestricted. The valve is larger as well. Standard Port Valves: As their name suggests, standard port valve are quite usual. This means they're less expensive than some alternatives. This type of valve has a smaller ball, and therefore the valve itself is smaller as well. The flow going through the pipe will in turn be smaller and will typically be about one pipe size smaller than the valve's pipe size. This makes it more restricted. The V Port Ball Valve: The V port ball valve is named after its V-shaped seat. What this means is that the orifice through which the product flows can be more easily opened and closed to change its direction. While many like this idea, the construction of this type of valve means that it can't be used just anywhere. It typically needs to be utilized in a more secure site. When the valve is opened, it is usually opened at the "small end" first, which helps stabilize the flow control. Trunnion Ball Valve: Then there is the trunnion ball valve, which doesn't exactly give much away through its name. This type of valve will actually anchor the valve at the top and the bottom through a particular mechanism. This would be applied on larger and more high pressure valves. While this type of valve isn't going to fit everyone's needs, it can definitely be used for particularly high pressure projects. Manually Operated Valves: Finally, these types of valves can be closed more quickly than their counterparts. Though this is an advantage in some cases, it also means that there can be a risk of a water hammer. These can include an actuator, which can be pneumatically or motor operated, which will in turn be used for on/off flow control. The valve will also have a positioner, which transforms the control signal into an actuator position. The flexibility of this type of valve is certainly an advantage to most projects. Now that you're more familiar with the styles and types of ball valves, you'll be in a better position to make decisions that will support your needs. For more information, please contact us today.