Five Facts About API Standards

Tony Mers • June 2, 2019

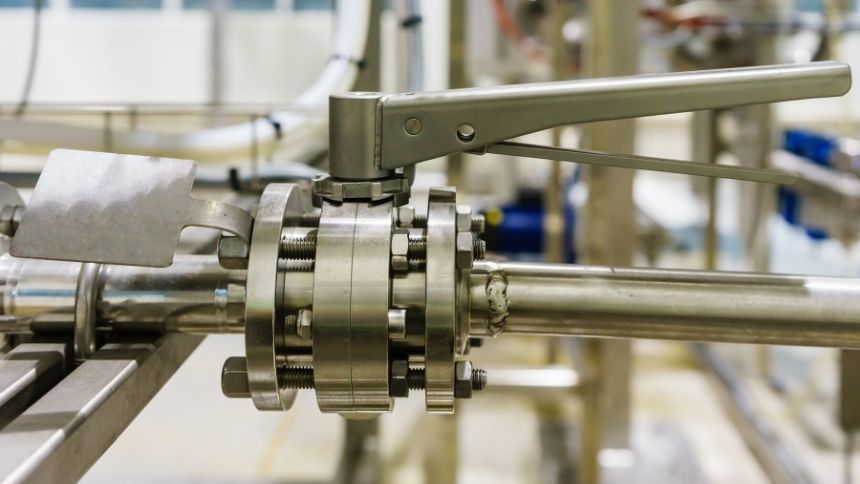

The American Petroleum Institute (or API) is an oil and gas industry trade association that oversees standards in oil and gas production. For example, API 6A defines the industry standards for wellhead and Christmas tree equipment and API 6D defines the industry standards for pipeline valves. Most people within the oil and gas industry have seen the phrase "API 6A valve" and "API 6D valve," but many may be unaware of what the API standards cover. Here are five facts about the API standards:

API Standards are Used Internationally

The International Organization for Standardization (or ISO) issues technical standards throughout the world. In the case of oil and gas production, the ISO has adopted the standards set by the API. For example, API 6A was adopted as ISO 10423 and API 6D was adopted as ISO 14313. Thus, hydraulic gate valves used in Saudi Arabia and the United States, the world’s leading oil producers each having 13% of the world's total oil production, will meet exactly the same technical standards.

API Standards Cover Specifications and Design of Valves

API standards cover everything about the design of a hydraulic gate valve, including the definition of "gate valve" as a "valve assembly with a gate operating within the body, 90 degrees to the conduit, to effect a closure." API 6A also covers the dimensions for a hydraulic gate valve, as well as the design of the threads, seats, and even the valve handwheel. For example, API 6A states that the handwheel must have spokes and must be replaceable while in service.

API Standards Cover the Manufacture of Valves

In addition to the design specifications, API standards also set specifications for the manufacture of hydraulic gate valves down to the hardness of the material used to make the valve and the chemical composition and dimensions of the welds. API 6A, for example, even specifies that welds must be made by qualified welders and records of the welders' performance qualification tests must be kept.

API Standards Cover the Quality Control, Testing, and Marking of Valves

API 6A also establishes standards for quality control to ensure that the manufacturing standards are met. These quality control standards specify the manner for measuring and testing products made in accordance with API 6A. Specifically, API 6A defines standards for the testing equipment, quality control personnel, and testing procedures. API 6A also specifies when and how repair welds and re-manufactured pieces can be incorporated into products covered by the standard. Aside from visual examination, API 6A also specifies when and how harness tests, tensile tests, impact tests, chemical analysis, visual inspection, and non-destructive tests, such as ultrasonic and radiographic tests, are conducted. For certain uses, such as natural gas production, pressure tests using nitrogen or other inert gasses may be conducted. The standards specify how records of the testing are maintained and how the products are marked to indicate both compliance with the standards and how the testing records may be traced for those products.

API Standards Vary Based on the Application

The API standards are not "one size fits all." In fact, API 6A specifies five product specification levels (or PSLs) for different applications. To assist the end user in selecting the PSL for the user's application, API 6A includes a flowchart in figure A.3 of annex A of the standard. Matching the right PSL to the right use is very important. For example, PSL 3G is specified for parts used in natural gas production and, as such, requires gas testing of parts, whereas other PSLs are not directed for natural gas production and, as such, usually do not require gas testing.

API 6A was written to ensure that oil and gas equipment is safe, reliable, and standardized. API standards cover everything from the design, materials, manufacture, testing, and marking of parts. In this manner, the end user can be assured that an API 6A hydraulic gate valve meets or exceeds the standards for quality and safety.

Right now, there are over 3,000 facilities on the Outer Continental Shelf involved in the collection and treatment of oil and gas. These oils and gases are collected from wells -- a process that's performed using certain types of high pressure valves. Of course, different types of American ball valves offer different results and it's crucial that the right projects are executed with the right types of valves. Quite often, the types of valves being used are ball valves, sometimes referred to as pig ball valves or pig vales (as they are used in conjunction with pipeline pigging systems). Before sourcing and investing in valves, it is important to understand the degree to which these valves may differ from one another. Let's delve into some of the defining characteristics of ball valve types. Ball Valve Body Styles Before getting into the exact types of ball valves that are available at the moment, it's important to remember that there are actually four separate types of body styles. These include the single body, split body, top entry, and welded styles. The styles of ball valves available differ from the types of ball valves available. This means that there are number of potential variations that you can see in ball valves. The great thing about this variety is that it means that there is more potential applicability in ball valves than there would be otherwise. Full Port Ball Valves: Turning to the different body types of ball valves, we can first look at the full port ball valve. A full port ball valve is defined by the fact that it has an oversized ball. The oversized ball has a purpose -- it is the same size as the pipeline. This means that there will be less potential friction less than there would be if the ball wasn't the same size as the pipeline, and the flow involved is unrestricted. The valve is larger as well. Standard Port Valves: As their name suggests, standard port valve are quite usual. This means they're less expensive than some alternatives. This type of valve has a smaller ball, and therefore the valve itself is smaller as well. The flow going through the pipe will in turn be smaller and will typically be about one pipe size smaller than the valve's pipe size. This makes it more restricted. The V Port Ball Valve: The V port ball valve is named after its V-shaped seat. What this means is that the orifice through which the product flows can be more easily opened and closed to change its direction. While many like this idea, the construction of this type of valve means that it can't be used just anywhere. It typically needs to be utilized in a more secure site. When the valve is opened, it is usually opened at the "small end" first, which helps stabilize the flow control. Trunnion Ball Valve: Then there is the trunnion ball valve, which doesn't exactly give much away through its name. This type of valve will actually anchor the valve at the top and the bottom through a particular mechanism. This would be applied on larger and more high pressure valves. While this type of valve isn't going to fit everyone's needs, it can definitely be used for particularly high pressure projects. Manually Operated Valves: Finally, these types of valves can be closed more quickly than their counterparts. Though this is an advantage in some cases, it also means that there can be a risk of a water hammer. These can include an actuator, which can be pneumatically or motor operated, which will in turn be used for on/off flow control. The valve will also have a positioner, which transforms the control signal into an actuator position. The flexibility of this type of valve is certainly an advantage to most projects. Now that you're more familiar with the styles and types of ball valves, you'll be in a better position to make decisions that will support your needs. For more information, please contact us today.