Are Your Valves Hurting Your Oil Productivity?

Tony Mers • July 1, 2019

Did you know that oil consumption in 2012 was at 89 million barrels and is only expected to grow up to 109 million barrels by 2035? Most people know that oil is a booming industry but the numbers are truly staggering. As these numbers continue to grow, so must the efficient productivity within the production of oil.

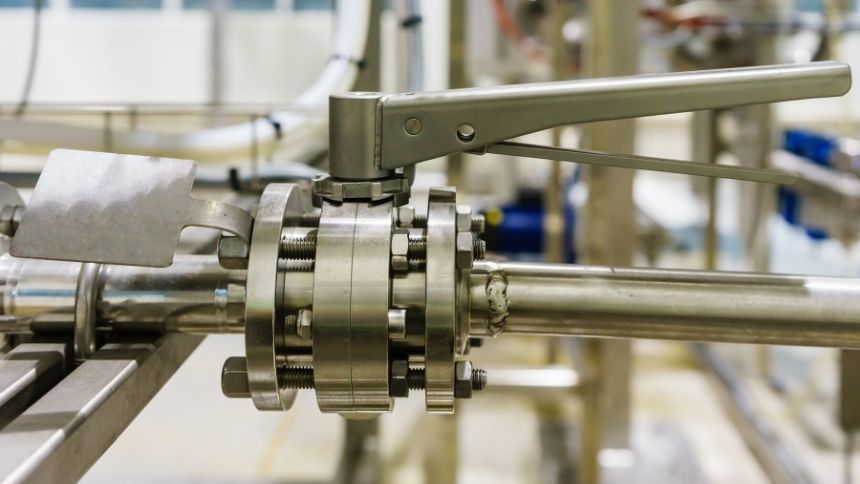

Valve supply should be an imperative business operation for oil companies in order to ensure maximum growth in production and to keep up with the continuing growing demand. High pressure valves, pig valves, gate valves, and so many more are important details to keep an operation running smoothly.

The stakes couldn't be any higher for oil rigs and operations to perform at a high functioning level. Sixty percent of the energy in the United States comes from gas and oil. This means that malfunctioning high pressure valves

could leave thousands of Americans literally in the dark.

Finding a high quality valve isn't always easy with tons of competition looking to tap into the lucrative oil and gas business. Researching a trusted company that's willing to look out for its clients and hold its valves to the highest standards is vital to the success of oil companies hoping to meet their own client needs. The last thing that oil companies should worry about is the possibility of broken high pressure valves and the right company will take that stress off your mind.

Over four billion metric tons of oil is produced globally every year. With people both nationwide and worldwide relying upon oil, finding a company looking to exceed industry standards is the best possible course of action. Not only is it important to find a company who makes an extremely high quality product but customer service should also be a consideration.

In the event that there is something that goes awry with a valve, whether it be new or old, the right company will provide quick and efficient service that will get it back up and running in no time at all. Productivity, assembly, testing, engineering, reliability, and efficiency are all imperative in ensuring a valve does not put the next city block over in the dark for the rest of the night.

Right now, there are over 3,000 facilities on the Outer Continental Shelf involved in the collection and treatment of oil and gas. These oils and gases are collected from wells -- a process that's performed using certain types of high pressure valves. Of course, different types of American ball valves offer different results and it's crucial that the right projects are executed with the right types of valves. Quite often, the types of valves being used are ball valves, sometimes referred to as pig ball valves or pig vales (as they are used in conjunction with pipeline pigging systems). Before sourcing and investing in valves, it is important to understand the degree to which these valves may differ from one another. Let's delve into some of the defining characteristics of ball valve types. Ball Valve Body Styles Before getting into the exact types of ball valves that are available at the moment, it's important to remember that there are actually four separate types of body styles. These include the single body, split body, top entry, and welded styles. The styles of ball valves available differ from the types of ball valves available. This means that there are number of potential variations that you can see in ball valves. The great thing about this variety is that it means that there is more potential applicability in ball valves than there would be otherwise. Full Port Ball Valves: Turning to the different body types of ball valves, we can first look at the full port ball valve. A full port ball valve is defined by the fact that it has an oversized ball. The oversized ball has a purpose -- it is the same size as the pipeline. This means that there will be less potential friction less than there would be if the ball wasn't the same size as the pipeline, and the flow involved is unrestricted. The valve is larger as well. Standard Port Valves: As their name suggests, standard port valve are quite usual. This means they're less expensive than some alternatives. This type of valve has a smaller ball, and therefore the valve itself is smaller as well. The flow going through the pipe will in turn be smaller and will typically be about one pipe size smaller than the valve's pipe size. This makes it more restricted. The V Port Ball Valve: The V port ball valve is named after its V-shaped seat. What this means is that the orifice through which the product flows can be more easily opened and closed to change its direction. While many like this idea, the construction of this type of valve means that it can't be used just anywhere. It typically needs to be utilized in a more secure site. When the valve is opened, it is usually opened at the "small end" first, which helps stabilize the flow control. Trunnion Ball Valve: Then there is the trunnion ball valve, which doesn't exactly give much away through its name. This type of valve will actually anchor the valve at the top and the bottom through a particular mechanism. This would be applied on larger and more high pressure valves. While this type of valve isn't going to fit everyone's needs, it can definitely be used for particularly high pressure projects. Manually Operated Valves: Finally, these types of valves can be closed more quickly than their counterparts. Though this is an advantage in some cases, it also means that there can be a risk of a water hammer. These can include an actuator, which can be pneumatically or motor operated, which will in turn be used for on/off flow control. The valve will also have a positioner, which transforms the control signal into an actuator position. The flexibility of this type of valve is certainly an advantage to most projects. Now that you're more familiar with the styles and types of ball valves, you'll be in a better position to make decisions that will support your needs. For more information, please contact us today.